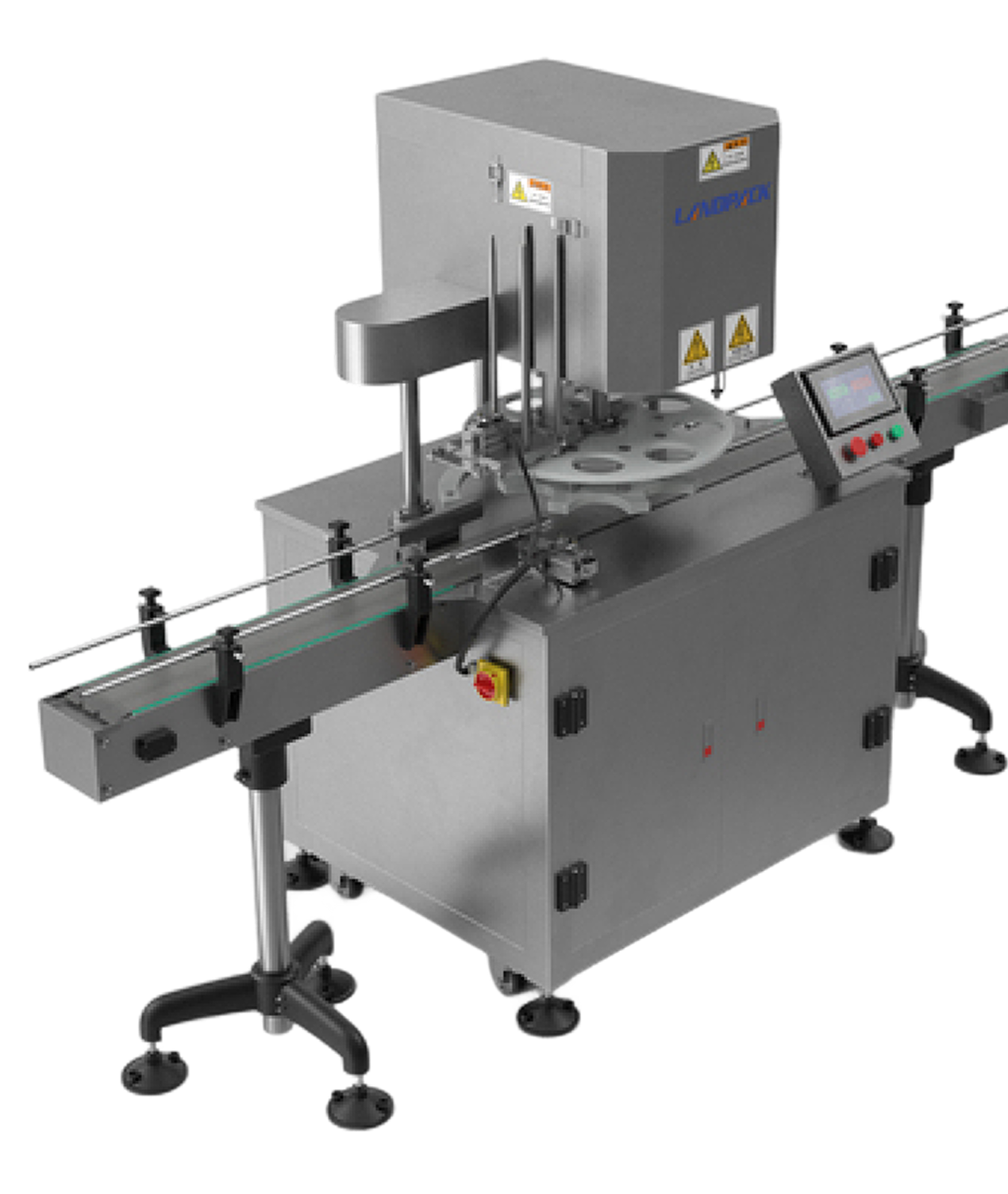

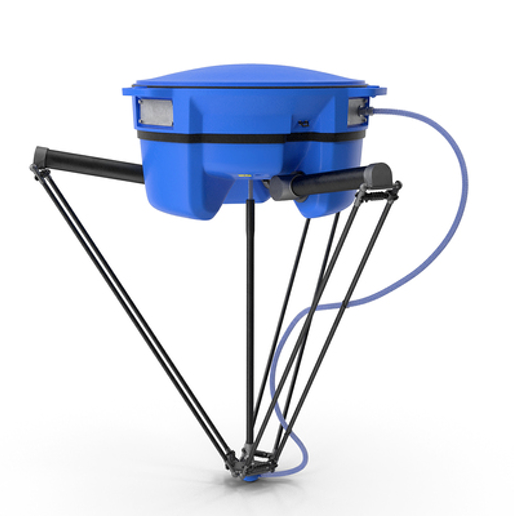

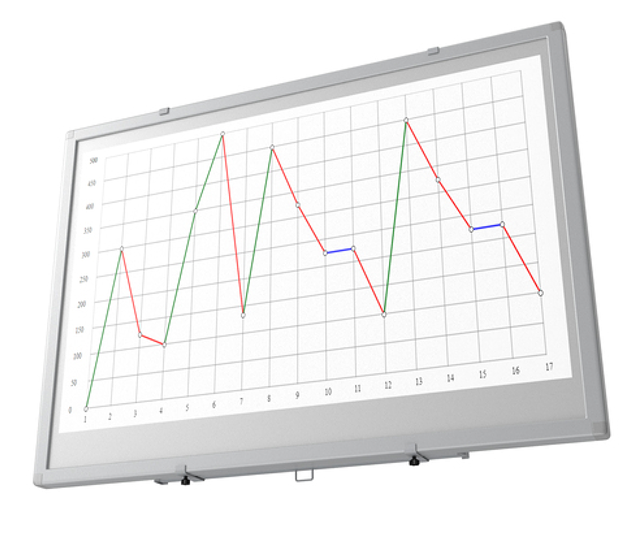

We cover the gamut of the manufacturing lifecycle: from production to tracking to maintenance. We ensure solutions that are strategically sound and actually used by the shop floor. Importantly, we do all this with an eye on what the future may bring - giving you a solution that meets today's requirements, and tomorrow's challenges.